I-Heat Shrink Insulating Tubing

Isicelo

1.Isetyenziselwa amandla ombane aphakathi ukuya kuthi ga kwi-36kV

2.Ukukhuselwa kumswakama kunye noxinzelelo

I-3.Ifanelekile ukupheliswa kwekhebula kunye nokukhusela okuphakathi kwe-insulation

Uphawu

I-1.I-adhesive yokunyibilika eshushu inika amanzi angcono

Uhlobo lwe-2.Ukwambathisa:ukwaleka ifilimu

3.Ukumelana nokugqwesa okugqwesileyo

4.Ukumelana ne-UV kunye nokumelana nemozulu

5.Halogen-free

6.Iipropati eziphezulu zombane kunye nezomatshini

7.Ukuncipha komlinganiselo 3:1

8.Udonga oluphakathi

Uphawu

1.Umsebenzi okhethiweyo wesixhobo sombane

2.I-insulation ethembekileyo

3. Superior hermetic sealing

4.Ubushushu obugqwesileyo / ubungqina obubandayo, ukungangeni kwamanzi, Ukuchasa ukuguga,

5.Isetyenziswa ngokubanzi kwibala lamandla ombane, i-elektroniki, i-petroleum, ubunjineli beekhemikhali, ulwakhiwo kunye nonxibelelwano

Imveliso yetyhubhu eshwabeneyo ubushushu kufuneka kuqala ikhethe i-masterbatch efanelekileyo, kwaye emva koko ukhethe izinto ezincedisayo ukuvelisa ezithile.

Indlu ye-thermal casing.

1. Inkqubo yokuvelisa ityhubhu encitshisiweyo yobushushu kukuqala ukuveliswa kwe-polyene leech masterbatch: ukudibanisa izixhobo ezahlukeneyo ze-polyene leech kunye nezixhobo ezahlukeneyo ezincedisayo.

Izinto eziphathekayo zilinganiswe ngokomlinganiselo wefomula kwaye zixutywe: izinto ezixutywe zifakwe kwi-twin-screw extruder kunye ne-pelletized ukuvelisa i-polyene leech esebenzayo masterbatch.

2. Inkqubo yokubumba imveliso: ngokwemilo yemveliso, iindlela ezimbini ze-screw extrusion kunye nenaliti yokubumba zingasetyenziswa.

Ukusetyenzwa kunye nemveliso:

1. Uhlobo lwe-screw-screw extrusion: ubukhulu becala lusetyenziselwa ukubumba i-extrusion yemibhobho yokutshisa ubushushu, efana netyhubhu enodonga olunye olushwabeneyo nobushushu, iityhubhu ezinodonga oluphindwe kabini olushwabene lushushu oluneglu, kunye nobungqingqwa obuphakathi.

Imibhobho yokucima ubushushu eludongeni, imibhobho yoxinzelelo oluphezulu yebhasi yebhari, imibhobho yobushushu obuphezulu eshwabeneyo kunye nezinye iimveliso zonke ziyacutshungulwa kwaye zenziwe nge-screw extrusion enye.

Umgca wokuvelisa ityhubhu ecuthekayo kufuneka ube nezi zixhobo zilandelayo: i-extruder (ukwenziwa kwetyhubhu yobushushu), ukungunda kwemveliso, itanki yamanzi okupholisa, isixhobo soxinzelelo, kunye

Isixhobo sediski, njl.

2. Isitofu sokubumba: ikakhulu sisetyenziselwa ukuveliswa kobushushu obunobushushu obukhethekileyo obufana neminqwazi yobushushu, iziketi zeambrela ezishwabeneka bubushushu, iibhedi zomnwe ezishwabene bushushu kunye nezinye iimveliso.

Bonke basebenzisa isitofu sokubumba, kunye nezixhobo zokuvelisa kufuneka zibandakanye oomatshini bokubumba inaliti kunye nenaliti yokubumba.

3. Inyathelo elilandelayo elibalulekileyo kukudibanisa iradiation cross-linking.Iimveliso ezenziwe nge-extrusion okanye i-injection molding iseyi-linear ye-molecular structures.

Isakhiwo, imveliso ayikabi nayo "umsebenzi wememori", kwaye ukusebenza kokumelana nokushisa, ukuguga, kunye nokuxhatshazwa kokugqoka akwanele.

Guqula i-molecular structure yemveliso.Indlela esihlala siyisebenzisa kukuguqulwa kweradiation crosslinking: i-electron accelerator radiation crosslinking, i-cobalt source radiation

Cross-linking, peroxide chemical cross-linking, ngeli xesha i-molecule iyatshintsha ukusuka kwi-linear ye-molecular structure ukuya kwi-network structure.Iimveliso ezikhutshiweyo zidlula

Emva kwe-cross-linking, ine "impembelelo yememori", eyandisa kakhulu ukuchasana kweqondo lokushisa, iipropathi zomatshini, kunye neempawu zeekhemikhali zetyhubhu yokushisa ukushisa.Itheyibhile ethile

Ngoku umbhobho wokutshisa ubushushu utshintshile ukusuka kwimeko yokunyamezela ukuya ekungahambelaniyo, ukumelana nokuguga, ukuxhathisa i-abrasion, kunye nokumelana nokubola kweekhemikhali.

4. Ukwandiswa kokubumba: Imveliso elungiswe yi-radiation crosslinking sele ine "memory memory effect", kwaye inokuphakama okuphezulu.

Ukusebenza okunganyibilikiyo phantsi kobushushu.Emva kokufudumeza kubushushu obuphezulu, ukufutha kwevacuum kunye nokupholisa, iba yityhubhu egqityiweyo yobushushu, kwaye ke ngokwetyhubhu.

Imeko yangempela yokupakishwa kwemveliso egqityiweyo kunye nokuvalwa nayo inokunqunyulwa kwaye iprintwe ngokweemfuno zabathengi.Ukupakishwa okuphakathi kwesiqhelo kukwakhona.

Ukusebenza

| Uvavanyo | Indlela yoVavanyo | Imfuneko |

| Ubushushu bokusebenza | UL 224 | -50 ukuya +125 ℃ |

| Tensile strength | I-ASTM D 2671 | ≥14 Mpa |

| Ukwandisa ngexesha lekhefu | I-ASTM D 2671 | >400% |

| Ukwandiswa ngexesha lekhefu emva kokuguga kobushushu | I-ASTM D 2671 158℃/168hrs | ≥300% |

| Ukuncipha kwexesha elide | UL 224 | 0±5% |

| Umlinganiselo wodonga oluyinxenye | I-ASTM D 2671 | <30% |

| Ukusilela komlilo | VW-1 | Dlula |

| Ukuxhathisa umthamo | IEC 93 | >1014Ω.m |

| Ukuzinza kobhedu | UL224 | Dlula |

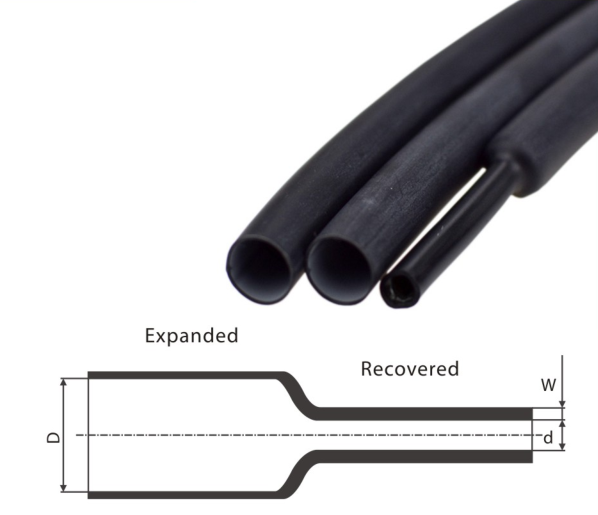

| Uhlobo | Uluhlu lweDiameter yeSicelo(mm) | Yandisiwe(mm) | Ibuyiselwe(mm) | |

| D(min) | d(ubuninzi) | W(min) | ||

| RSG-15/5 | 4.5-8 | 15 | 5 | 1.5 |

| RSG-20/8 | 6.5-14 | 20 | 8 | 1.8 |

| RSG-28/10 | 12-18 | 28 | 10 | 1.8 |

| RSG-35/14 | 17-27 | 35 | 14 | 2 |

| I-WRSG10-28/10 | 6.5-14 | 28 | 10 | 2.2 |

| I-WRSG10-34/14 | 17-27 | 34 | 14 | 2.3 |

| I-WRSG10-40/18 | 17-30 | 40 | 18 | 2.5 |

| I-WRSG10-50/20 | 17-35 | 50 | 20 | 2.5 |

| I-WRSG35-50/20 | 17-35 | 50 | 20 | 3 |

| I-WRSG35-60/22 | 21-45 | 60 | 22 | 3 |

| I-WRSG35-70/25 | 24-52 | 70 | 25 | 3 |